Quality control of products

Are you worried about the quality of the product before paying the balance?

Don’t worry! Aimlux has a complete and strict quality control process as a professional LED road product supplier.

- Aimlux prioritizes quality control through stringent incoming material inspection and adherence to SOP (Standard Operating Procedure) standards.

- Aimlux will work on a strict quality inspection for every step of LED road product production.

- Aimlux will provide pictures and videos of LED road product quality inspection and a quality inspection checking list.

Let’s see how we do it.

Table of Contents

Pre-Production

Aimlux prioritizes quality control through stringent incoming material inspection and adherence to SOP (Standard Operating Procedure) standards.

1. Incoming Material Inspection

All incoming materials are subject to rigorous inspection to ensure they meet our quality standards.

2. Sample Sealing and Approve

First samples are sealed and sent to customers for approval before mass production begins.

3. SOP Check

Comprehensive checks are conducted to ensure adherence to SOPs (Standard Operating Procedures) during production.

4. Production Tool and Fixture check

Tools and fixtures used in production are inspected to guarantee reliability and consistency.

During Production

Aimlux will work on a strict quality inspection for every step of LED road product production.

1. Efficient and Advanced Assembly Line and Equipment

Our assembly line is equipped with cutting-edge technology and manned by skilled workers for efficient production.

2. Experienced Workforce

Our experienced workforce ensures precision and attention to detail at every stage of production

3. Key Position Deployment

Key positions are assigned to personnel with specialized skills to maintain quality standards.

4. Production Inspection

Regular inspections are conducted during production to identify and rectify any issues promptly.

Post-Production

Aimlux will provide pictures and videos of LED road product quality inspection and a quality inspection checking list.

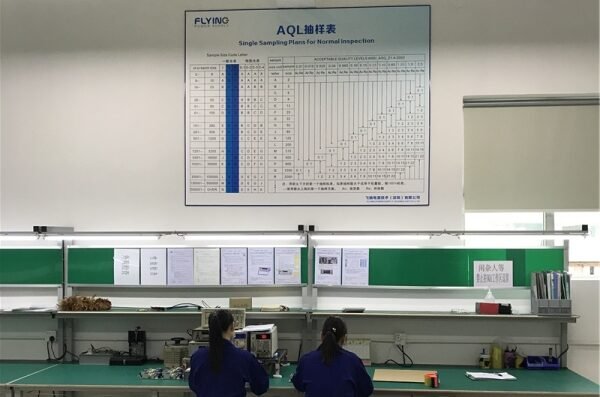

1. Random Sampling Based on Quality System

Post-production inspections are based on our comprehensive quality system, involving random sampling for thorough assessment.

2. Comprehensive Testing Reports

For each order, we provide a complete set of IES (luminaire photometry), integrating sphere, IP (Ingress Protection), and IK (Impact Protection) testing reports.

3. Product Quality Inspection Reports

Each order includes detailed product quality inspection reports, product and test images, and product warranty certificates. Traceable Warranty Period

Traceable during warranty

At Aimlux, we prioritize traceability and quality assurance through our ERP (Enterprise Resource Planning) system, which includes robust material and product coding processes.

1. Material Serial Number Archiving

Use ERP systems to assign unique material codes to all incoming materials. Each material is accurately recorded and tracked, ensuring transparency and traceability throughout the production cycle.

2. Production Records Archiving

Detailed production records are maintained and archived for quality assurance and post-sale support.

3. Unique Traceable Serial Numbers

Each product is assigned a unique and traceable serial number for easy identification and warranty tracking.